| |

|

|

STRING WOUND CARTRIDGE

• Sizes : 10”, 20”, 30”, 40”, 60”

• Diameter: 2”,2.5”, 4”, 6”,8”,

• Micron Rating: 0.5, 1, 5, 10, 25 & more

• Material of Construction : |

|

| |

• Polypropylene with

Polypropylene core,

• Polypropylene with SS core

• Cotton with SS core

• Glass fiber with SS core

• Ryton, Polyester & more |

|

• NSF & FDA approved cartridge |

SPUN BONDED

CARTRIDGE

• Sizes : 10”, 20”, 30”, 40”

• Diameter : 2.5”, 4”, 6”, 8”

• Micron Rating : 0.5, 1, 5, 10, 25 & more

• Material of Construction : |

|

|

|

•

Polypropylene with Polypropylene core,

• Polypropylene with fused core

• Grooved Spun |

• Type :DOE, CODE 7

• Nominal & absolute filtration rating

• NSF & FDA approved cartridge |

|

UV SYSTEMS. |

|

BENEFITS OF

UV SERIES

• Reliable and consistent UV

disinfection efficiency.

• High quality and afford ability.

• Simple Installation and maintenance

• Compact units requiring minimum space.

• Easily adaptable to varied site conditions

• SS 316 – the preferred choice of industries due to high

corrosion resistance.

• Quartz glass & Teflon technology for superior UV

transmission |

|

| |

|

|

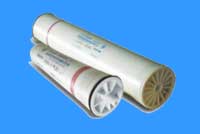

MEMBRANES |

|

|

MBR

(Membrane Bio Reactor)

Membrane Bio Reactor systems

combine proven ultra filtration technology with biological

treatment for municipal, commercial and industrial

wastewater treatment and water reuse applications. The

membrane bio reactor system incorporates reinforced hollow

fiber membrane specially designed to meet the requirements

of wastewater treatment. |

|

|

PUMPS |

|

|

HIGH

PRESSURE PUMPS : DP

Vertical DP Pumps offer on

exclusive range of pumps wetted parts of which are made of

Stainless Steel AISI 304 (DPVS Series). And AISI 316 (DPVS

Series) We have in house service station and trained persons

for service of pumps with spares stock. |

|

|

|

|

|

VERTICAL

AND HORIZONTAL PUMPS

CDL/CDLF and CHL Series pumps

are a wide range of Non-Self Priming Multistage centrifugal

pumps which are driven by standard motors. |

|

|

|

|

|

ROTARY VANE

PUMPS

Rotary Vane pumps range from

Mini-Compact, Standard and Maxi pumps depending upon the

requirement from 400ltrs. To 1000ltrs. Both in SS and Brass

pumps. We supply them both as bare and with motors. We have

a tie up with an established motor requirement. We also

supply spares and give service for the pumps. |

|

|

|

|

|

CHEMICAL

DOSING PUMPS

Solenoid driven diaphragm

dosing pumps with wall/foot mounting with Hc1 Series to Hc3

series with capacity varying from 004LPH to 15-08 LPH. |

|

|

SOLAR HEATER & SS

TANK |

|

|

SOLAR

HEATER & SS TANK

Manufacturing of solar water

heater and SS Water Tanks of high storage capacity, mode by

stainless steel sheets of 16-14-12-10 gauge thickness and

316/304 grades along with high Quality Welding Rhodes. |

|

|

|

|

|

VESSELS |

|

|

VESSELS

• 100% non-metallic

construction

• One piece seamless molded vessel with weld or joints.

• About 1/3 the weight of steel tanks and can be handled

easily.

• Available in standard polyester or chemical resistant

Vinyl ester construction depending on your needs.

• Optional custom openings located as per your

specifications.

• Easy to handle and install. |

|

|

|

|

|

VALVES, INSTRUMENTS &

SPARES |

|

|

|